What is Reactive Dye? Properties and reaction of Reactive dye, Classification of Reactive Dyes

Content :

Reactive Dye

Structure & properties of Reactive Dyes

Reaction of Reactive dyes

Dye take up of Reactive dye

Classification of Reactive dyes

Reactive dyes

- For a long time, chemist had been seeking a

method of joining dye with cellulose through

covalent bond.

- At the end of 1940, chemists turned their

attension to the dyes containing cyanuric chloride

or triazinyl dyes

- It is possible to make chlorine atom

in cyanuric chloride to combine

with hydroxyl or amine group of

dye molecules

|

| Reactive Dye |

An outstandingly important property of

cyanuric chloride is that if any chlorine atom

left unsubstituted, that can react to cellulose.

• The reaction of DCT with cellulose is shown

below

|

| reaction of DCT with cellulose |

If hydrolysis occurs, that will decrease the

color yield and reactive dye converts into a

sort of direct dye which is very substantive to

the cellulose and also create problem in

washing off leading to poor wet fastness

Exploitation of the

dichlorotriazine reactive

system soon led to parallel

development of the much

less reactive

mono chlorotriazine dyes,

readily made by a

substitution reaction

between an aryl amine and

the dichlorotriazine

precursor.

|

| Reaction between an aryl amine and the dichlorotriazine precursor. |

• More stable padding liquors

could be prepared using the

aminochlorotriazine types

Reaction of Reactive Dyes

Remazol (HOE) dyes, based on the 2-sulphatoethylsulphone

precursor of the vinysulphone reactive system or related species,

function by a nucleophilic addition mechanism rather than

substitution.

• Before this can occur, however, alkaline 1,2-elimination of the

precursor grouping is necessary to release the reactive

vinylsulphone system.

• In this system the carbon–carbon double bond is polarised by the

powerfully electron-attracting sulphone group.

• This polarisation confers a positive character on the terminal carbon

atom, favouring nucleophilic addition of either a cellulosate anion

or a hydroxide ion, again leading to either fixation or hydrolysis

respectively

Reactive dyes (Bifunctional)

• The appearance of two further interesting ranges of

bifunctional dyes that are capable of reacting with

cellulose via both mechanisms, nucleophilic substitution

and nucleophilic addition.

• In both systems one ring substituent in a

halogenotriazine dye carries a 2-sulphatoethylsulphone

grouping .

• The halogeno substituent can be either chlorine or the

more reactive fluorine.

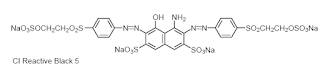

The four solubilising groups in the precursor form of CI Reactive

Black 5 confer high solubility but unusually low substantivity.

• It is a nearly symmetrical bis(sulphatoethylsulphone) structure

and as these precursor groups lose their ionic charge by 1,2-

elimination, the substantivity for cellulose is enhanced and the

bis(vinylsulphone) structure formed shows excellent fixation

efficiency under alkaline conditions.

Aminofluorotriazine sulphatoethylsulphone dyes

• Early in 1988 Ciba-Geigy launched the Cibacron C range of mixed

bifunctional dyes.

• They contain a new aliphatic vinylsulphone system and either a

monofluorotriazine bridging group or an arylvinylsulphone function.

• They are designed mainly for pad applications and appear to be

characterised by medium to low affinity, good build-up, easy wash-off and

high fixation.

• Their outstanding bath stability and high fixation make them especially

suitable for pad–batch dyeing.

• The manufacturing cost of these structures is believed to be relatively high

but the purchase cost to the dyer may be offset by enhanced costeffectiveness in use attributable to efficient fixation and easy wash-off,

possibly the best approach that time towards environmentally acceptable

reactive dyes.

Structure and properties of reactive dye

• The design of reactive dye structures almost always involves one or

more compromises between conflicting requirements.

• There is seldom an ‘ideal’ structure of a desired hue that embodies

all possible attractive features with regard to application and

fastness properties.

• The gain in aqueous solubility provided by an extra sulpho group

often has to be paid for by a decrease in affinity for cellulose.

• Enhancement of substantivity is beneficial for high exhaustion but

may impair migration or washing-off characteristics.

• High reactivity offers the possibility of rapid fixation but storage

stability may be adversely affected.

Reactive dyes uptake

• All conventional reactive dyes for cellulose, irrespective of

whether they react by nucleophilic addition, substitution,

or both mechanisms rely on the reactivity of the cellulosate

anion as the nucleophilic reagent and hence hydrolysis of

the dye by reaction with hydroxide ions from water will

always compete with the desired fixation reaction.

• Reaction between the dye and cellulose can occur only

when the dye has been absorbed into the cellulose phase.

Thus the kinetics of the dye–cellulose reaction are strongly

influenced by the rate of absorption of dye.

• The ratio of the rate constants for reaction of the dye with

the fibre and with water is a constant for a given dye over a

wide range of alkaline pH values.

Factors governing dye uptake

The efficiency of fixation is a function of:

1. The substantivity ratio, the relative concentrations of

dye absorbed into the substrate and remaining in the

dyebath;

2. The reactivity ratio, the ratio of rate constants for the

fixation reaction and hydrolysis;

3. The diffusion coefficient of the dye in the substrate;

4. The liquor ratio; and

5. The surface area of the substrate available for

absorption of dye.

Factors governing dye uptake

• The lower the linear density of the fibre, i.e. the

greater the surface area per unit weight, the more

efficient is the dyeing.

• The substantivity ratio is the most influential of the

factors governing fixation efficiency. Dyes of higher

substantivity diffuse more slowly than less substantive

dyes.

• Changes in dyebath conditions that increase

substantivity tend to decrease the diffusion coefficient.

• Lowering the liquor ratio favours increases in the rate

and efficiency of fixation.

• An increase of dyeing temperature lowers the

substantivity ratio and accelerates the rate of

hydrolysis of the dye; both of these effects

reduce the fixation efficiency.

• The rates of diffusion into and reaction with the

fibre are also accelerated, however, and these

factors both favour fixation of the dye.

• An increase in electrolyte concentration always

enhances substantivity without impairing

reactivity providing the dye remains completely

dissolved.

D

Classification of reactive dyes

Alkali-controllable reactive dyes:

• These dyes have optimal temperatures of fixation

between 40 and 60°C.

• They are characterized by relatively low exhaustion in

neutral salt solution before alkali is added.

• They have high reactivity and care in addition of alkali

is necessary to achieve level dyeing, preferably at a

controlled dosage rate.

• Typical examples of dyes belonging to this group have

dichlorotriazine, chlorodifluoropyrimidine, and

vinylsulphone reactive systems.

Salt-controllable reactive dyes

• Dyes in this group show optimal fixation at a

temperature between 80°C and the boil.

• Such dyes exhibit comparatively high exhaustion

at neutral pH, so it is important to add salt

carefully to ensure that dyeing is level.

• Electrolyte addition is often made portion wise or

preferably at a controlled rate of dosage.

• Dyes with these properties typically have lowreactivity systems such as trichloropyrimidine,

aminochlorotriazine or bis(aminochlorotriazine).

Temperature-controllable reactive dyes

• This group is represented by those dyes that react with

cellulose at temperatures above the boil in the absence of

alkali, although if desired they can be applied under the

same conditions as the salt-controllable group with alkaline

fixation at a temperature between 80°C and the boil.

• Dyes in this group have self-levelling characteristics so

there is no need to use auxiliary products to facilitate level

dyeing.

• Good results can be achieved by controlling the rate of

temperature rise. At present only the Kayacelon React (KYK)

range of bis (aminonicotinotriazine) dyes belong to this

group.

Post a Comment

Post a Comment